|

|

|

|

|

|||||

|

||||||||

The Intelligent Serial I/O Boards |

|||

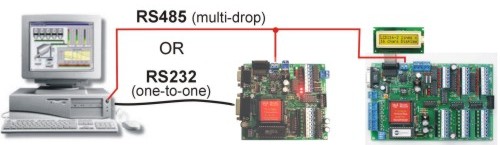

T hanks to the many built-in communication protocols, the Super PLCs also make more than great serial-based I/O boards for PCs or Workstation!

You can use the T100MD's RS232 port for straightforward connection to a PC. With an RS232-to-RS485 adapter (such as the Auto485 ) as many as 31 super PLCs can be connected to a single PC to provide distributed I/Os at up to 4000 ft away. Click here to view a sample Visual Basic communication program which is provided to aid Visual Basic programmers to rapidly learn how to talk to our PLCs using the native protocol.

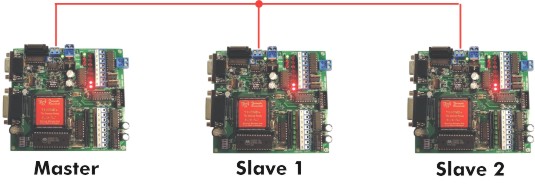

The T100MD+ supports a few standard communication protocols as follow: 1) Native ASCII based protocols, e.g. "@01RI00nn*" Our proprietary ASCII based native protocol allows you to read or write to every I/O and internal variable within the PLC using a rather straightforward command/response exchange of ASCII strings. Please see the T100MD+ User's Manual Chapter 3 and 4 for detailed description of these protocols. A The MODUS ASCII and RTU protocols are simple but popular communication protocols and you can find their documentation at http://www.modbus.org/ . The memory mapping of T100MD PLC to the MODBUS registers can be found in Chapter 5 of the T100MD+ User's Manual . In addition, you can even implement your own proprietary communication protocol using the powerful TBASIC language! This allows a T100MD+ to be used with an obscure host computer that must use a certain fixed, proprietary serial protocol to control external I/Os. E very T100MD+ PLC has built-in TBASIC commands (such as NETCMD$, READMODBUS, WRITEMODBUS) for communicating with another PLCs or 3rd party MODBUS devices. Hence it is possible for one or more T100MD+ to be used as slave I/O boards for a master T100MD+ PLC. This makes it possible to use more analog or special I/Os than are available on a standard T100MD+ PLC for complex control tasks. Example, in the arrangement shown below the master PLC could have access to 24 analog I/Os, 6 PWMs, 6 stepper controllers and 6 encoder inputs!

|

|||

|

|||

Fibre Optics Communication |

|||

By using RS485-to-Fiber Optics converters, you can use the M-series PLCs as remote I/O boards via Optical Fiber! This allows the communication cable to be laid across open field where lightning risk can cause severe damage to copper wire based communication links. On request by a customer we tested one such converter made by R.E. Smith (www.rs485.com, model FC485) as shown in the following diagram:

The plan is to have a master PLC collect data from the 20 plus slave PLCs in the plant floor and the data will become available to the corporate intranet for real-time production reporting and analysis via the corporate Intranet. However, the customer requires that the master PLC be housed in the enterprise server room to acquire data from the 20 slave PLCs on the plant floor. The server room and the plant are in two separate buildings with a car park in between and the company is located in a tornado country with multiple lightning strikes every year. Optical fiber is the only feasible means of communication. We tested the above setup and it works flawlessly and the customer now has a reliable, standalone master PLC automatically collect production data and delivered to the management via the web browser. |

|||